BRILLIANCE APPAREL

Head Office in Singapore

Branch Office in Hong Kong

Established in 2023

Total Workforce 4700 people

Total 9 Factories in Sri Lanka

Manufacturing Woven Tops / Cut & Sewn Knits

Total Manufacturing Capacity 900,000pcs / Month

Brilliance Apparel (Singapore)

South Asia

Smart Shirts Lanka

(Factory)

Brilliance Apparel Lanka (Import & Export)

K1

K2

K3

K4

K5

K6

K7

K8

K9

GEOGRAPHIC LOCATION

K1 - 5mins drive from Airport / 1hr drive from Colombo port

K2 - Walking Distance from K1

K3 - 5mins drive from factory 1.

K4 - 3.5~4hrs drive from factory 1.

K5 - 5hrs drive from factory 1.

K6 - 1hr drive from factory 1.

K7 - 45mins drive from factory 1.

K8 - 3.5~4hrs drive from factory 1.

K9 - 2 hrs drive from factory 1.(Established Jan 2022)

PRODUCTION CAPACITY

FACTORY

CAPACITY PER DA

GARMENT CAPACITY

(PCS / MONTH)

(PCS / MONTH)

K1 (Woven & Knit)

5,500

132,000

K3 (Woven & Knit)

9,000

216,000

K4 (Woven)

4,500

108,000

K5 (Woven)

9,000

216,000

K6 (Woven)

3,500

84,000

K8 (Woven)

4,000

96,000

K9 (Woven)

2,500

60,000

TOTAL

912,000pcs

FACTORY INTRODUCTION

– FABRIC LAB

– FABRIC LAB

A well-equipped laboratory with a well-trained team to facilitate most of the advance testing requirements from customers

Lanka LAB has accredited by NORDSTROM & LLBEAN customers

FACTORY INTRODUCTION – WAREHOUSE & CUTTING

Cutting Capacity (Woven & Knits)

CUTTING FACTORY

OUTPUT PCS / DAY

OUTPUT PCS / MONTH

K2

18,500

444,000

K7

20,000

598,000

Total

38,500

924,000

- Total space of warehouses – 7,576 sq. meters

- Total space of Cutting – 8,845 sq. meters

- Incoming Material Inspection (based on AQL 2.5)

- 100% Cut panel inspection facility before sewing

FACTORY INTRODUCTION

– EMBROIDERY

– EMBROIDERY

EMBROIDERY CAPACITY

FACTORY

CAPACITY

STITCHES / DAY

K2+K7

8,000,000

Main facilities located at factory K2 and K7, our in-house set-up is able to cater for all needs from chest logos to overall garment panel embroideries.

FACTORY INTRODUCTION

– QA & FINISHING

– QA & FINISHING

SPECIAL VQP PROGRAMS (VENDER QUALITY PROGRAM) – POLO

a) Certified by Polo

b) Every year asses them & renew the certification

b) Every year asses them & renew the certification

c) Well established audit rooms for smooth functioning of VQP

DEDICATED QA TEAM FOR OTHER MAJOR CUSTOMERS

Dedicated QA team to handle Nordstrom / Dillard’s / L.L. Bean / Lacoste

FACTORY INTRODUCTION

– WASHING & DIPPING

– WASHING & DIPPING

Washing Capacity

PRODUCT

TYPE

CAPACITY

PCS / DAY

Tops

18,000

Knits

12,500

Bottoms

4,000

MANUFACTURE EXCELLENCE – QUALITY ASSURANCE & TQM

PROCESS IMPROVEMENTS FOR PREVENTION OF QUALITY FAILURES:

- Self–check initiatives & monitor individual performance of operators through SPS.

- Provide training & certification to the QC to ensure the effectiveness of the 100% inspection process.

- QA will focus on the pre-production and in-line manufacturing processes to prevent possible quality issue during the bulk production.

- Improve quality through deskill processes (Automation / Template Sewing) to less dependent on employees’ skill

- Continue to enhance the TQM at shop floor and follow up its effectiveness and progress on daily basis.

- Better handling of the rejected & garments to be repaired with clear identification.

- Maintain low WIP (Work In Progress) on the shop floor for better visibility on the manufacturing process.

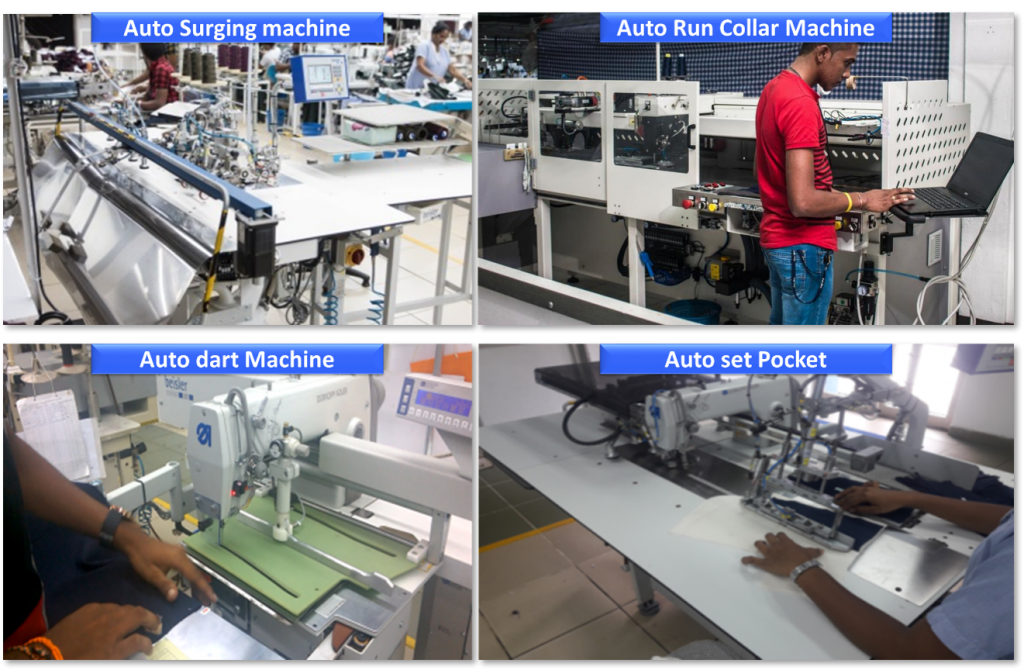

INVESTMENT ON AUTOMATION

Our investment on automations with the ultimate goal to improve the final product quality as well as the efficiency.

The latest investment on SPS (Smart Production System) with it’s built-in AI (Artificial Intelligence) system controlling the production flow and manage the sewing line.

The latest investment on SPS (Smart Production System) with it’s built-in AI (Artificial Intelligence) system controlling the production flow and manage the sewing line.

It has allowed the supervisors to spend more time on training the machine operators to improve their skill level and output quality.

TEAM BUILDING AND CSR ACTIVITIES

Main areas of compliance is focused on:

- Labor standards

- Health & Safety

- Environmental practices

- C-TPAT

Creating a pleasant working environment for the employees.

Various community activities and donations

INTERNATIONAL ACCREDITATIONS & CERTIFICATIONS

- WRAP (World-wide Responsible Accredited Production (Gold certificate)

- ISO 9001 : 2015

- GOTS (Global Organic Textile Standards) / OCS (Organic Content Standard)

- GSV (Global Security Verification)

- SUPIMA Cotton Certification

BRILLIANCE APPAREL QUALITY POLICY

We are as Brilliance Apparel, leader of manufacturing garments committed to provide unique experience for the satisfaction of our interested parties to fulfill their needs and expectations, requirement of the ISO standard by considering the Internal and external issues.

The level of quality is continuously improved through implementation of a quality management system, which is constantly monitored for its effectiveness by considering the risks and opportunities of the operation.